Frequently asked questions

Here you will find some common questions and the appropriate explanations about our product range. If you have any further questions, please do not hesitate to contact us.

Assembly aid & instructions

For free-standing units, we recommend foundations made of concrete (B25), with a dimension of 450 x 450 mm per side of the frame. For smaller units, a continuous foundation with the following dimensions is required: system width + 450 x 450 mm. Depending on the soil conditions, the foundation must be enlarged. The foundation depth should be at least 700 mm, depending on the frost line in the ground. Before excavation, it is advisable to obtain a division plan from the responsible office about the planned installation site so that pipelines, electric cables, etc. are not damaged.

Please ensure that the cables are pulled in before concreting.

If the system is concreted into a concrete foundation, the inlet depth for the stand elements should be 350 mm - 500 mm.

If the system is screwed onto a concrete foundation, bolt anchors (diameter 10 - 12 mm) or equivalent must be used.

For finishing the screw connection or the transition into the ground, we recommend our covering rosettes.

When mounting letterbox systems on house walls, the corresponding recommendations of the roof manufacturers must be observed depending on the wall composition. Furthermore, it must be ensured that no cold bridges are created by the fastening screws. If necessary, use special dowels for wall insulation. For the calculation of the total weight of the systems, please refer to our weight specifications in the detailed information.

1. Check

The wall to which the letterbox system is to be attached must be clean and level. Make sure that the wall has the appropriate load-bearing capacity. A letterbox weighs between 5 and 18kg, depending on its size.

2. Measuring

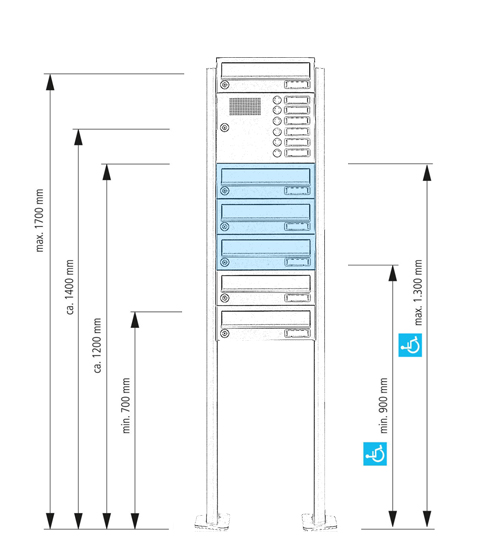

Measure the mounting holes on the back of the unit. Transfer these measurements to the wall. Please observe the mounting height prescribed by DIN 13724. The centre line of the lowest insertion opening should not be less than 700 mm. The centre line of the top insertion opening should not be higher than 1,700 mm. Only in exceptional cases (accessibility) is the lower limit 400 mm and the upper limit 1,800 mm permissible.

3. Drilling

Drill holes in the wall and insert dowels into the holes. Attention: Hole sizes and types of screws depend on the respective wall condition and must therefore be determined by the customer. If in doubt, please seek expert advice on site.

4. Screwing

Open the doors of the boxes in which the fixing holes are located and insert the appropriate screws with the spacers into the holes. Screw the system together. This step is best carried out by three people.

Our flush-mounted systems are equipped with pre-punched cable inlets on all sides, which can be removed very easily if necessary. We recommend that the installation of flush-mounted systems be carried out by a master craftsman, as cold bridges can occur when systems are installed in house walls if the insulation layer is interrupted during installation.

1. Measure height and width

Take the exact width and height from the back of the letterbox. This is important because you need the dimensions without the plaster cover frame. Add approx. 20 mm to these dimensions in both height and width and then draw a rectangle with these dimensions on the wall where the system is to be installed. Please observe the mounting height prescribed by DIN EN 13724. The centre line of the lowest slot should not be less than 700 mm, and the centre line of the top slot should not be higher than 1,700 mm. Only in exceptional cases is the lower limit 400 mm and the upper limit 1,800 mm permissible.

2. Measure the depth

Now measure the total depth of the letterbox system, add 5 to max. 10 mm here.

3. Break out the niche

Then break out a niche from the wall within the marked rectangle and at the depth of the plant.

4. Fit in the plant

Then carefully fit the plant into this niche and, if necessary, correct the niche size.

5. Drilling

Position the unit in the final position and mark the drill holes on the wall. Remove the unit from the niche and drill the corresponding holes in the niche wall and insert the dowels into the holes. Caution: Hole sizes and types of grommets depend on the respective wall properties and must therefore be determined by the customer. If in doubt, please seek expert advice on site.

Tip: The system can also be attached via the side walls.

6. Screw down

Now insert the unit into the niche again, open the doors of the boxes in which the fixing holes are located and insert the appropriate screws through these boxes into the dowels. Screw the system together. Make sure that the plaster cover frame completely covers the niche.

In order to achieve optimum water protection for your mail, the system/mailbox should be equipped with projecting cladding or a rain cover, and if possible the mailbox or mailbox system should be located under a canopy. Mail is only protected from water if it is completely deposited in the box and the access flap is closed. Mail that is not fully inserted allows moisture and dirt to penetrate the letterbox. It is therefore necessary to plan sufficiently dimensioned letterboxes for the upcoming demand. We offer extra letterbox depths for increased mail volumes, and we are also happy to manufacture customised sizes. In certain extreme weather conditions, water can still enter (according to DIN EN 13724 up to 1ccm). This is not a reason for complaint.

Installation direction

In a letterbox system, the mail is protected from wind and weather. However, when installing a free-standing system, make sure that the front of the box does not face directly towards the weather side.

Our complete sets are usually ready for connection! We already carry out the programming for complete sets in our factory.

However, we always recommend having the electrical installation carried out by an electrician. Please always refer to the manufacturer's operating instructions for wallboxes, intercom systems and video systems!

Camera, intercom or wallbox preparation

We offer the preparation of cameras, intercoms and wallboxes from various manufacturers for our systems. The preparation does not include any end devices, it is the provision of the screw mounts, drill holes & holes. So that you can mount your end unit without any problems.

General warnings

Our light and bell modules as well as our light and bell push-buttons may be operated with a maximum of 12-24 volts! A transformer with a VDE mark must be used! A higher voltage can endanger human life and lead to the cancellation of the warranty. Only components with 100 % permissible duty cycle may be connected to the push-buttons and modules! Failure to observe this warning may result in: - Fire hazard - Personal injury - Destruction of components Installation and assembly of electrical equipment may only be carried out by a qualified electrician! Please check whether the power consumption of the standard mains unit is sufficient for your planned consumption (e.g. for bell, intercom, light control as well as cable length and cross-section).

Light push-button/bell push-button DR29 for designers

Light pushbuttons/bell pushbuttons as individual pushbuttons are used to switch on the lighting in the entrance area and/or a staircase or to activate a signal transmitter. They may only be connected to extra-low voltage (12 V DC).

Light pushbutton/bell pushbutton Grothe Protact

Light pushbuttons/bell pushbuttons as individual pushbuttons are used to switch on the lighting in the entrance area and/or a staircase or to activate a signal transmitter. They may only be connected to extra-low voltage (max. 24 V AC/DC, 1.5 A).

LED light

If our LED luminaires have not been completely prewired and connected by us, please note that they may only be operated at 12 V DC. Other voltages will destroy and shorten the life of the LED luminaire.

Caution: Always ensure correct polarity with DC voltage.

If your letterbox is in its original packaging, your keys will be in the letterbox (removed via the flap) or in the enclosed bag (which also contains the assembly aid and other small parts).

Every letterbox that leaves our premises is carefully checked and packaged. A declaration of care is enclosed by the employee who manufactured your new product. Should you still not be able to find your key, please do not hesitate to contact us.

DIN norms

DIN EN 13724

When planning a letterbox system, it is essential to observe the currently valid DIN EN 13724 (also known as the "letterbox standard") so that you or your tenant do not have any problems receiving mail.

DIN EN 13724 guarantees:

• Problem-free mail delivery without bent letters or personal collection from a post office, e.g. Large DIN C4 envelopes

• Enough storage space for large volumes of mail

• No hassle with wet mail

• Best quality due to specified and tested materials

• Security against rent reductions due to standardised letter boxes

Our products are generally all in accordance with this standard. Our products are generally all tested according to this standard and marked accordingly. Only a few do not comply with this standard. You can find out more here

It is common to find information on DIN formats that fit into the corresponding letterbox opening. Here is a brief overview of the dimensions of the most common formats:

DIN A5: 148 x 210 mm

DIN A4: 210 x 297 mm

DIN A3: 297 x 420 mm

DIN B5: 176 x 250 mm

DIN B4: 250 x 353 mm

DIN B3: 353 x 500 mm

DIN C5: 162 x 229 mm

DIN C4: 229 x 324 mm

DIN C3: 324 x 458 mm

Material science

1.4301 is also known as X5CrNi18-10, AISI 304 or V2A steel. It accounts for around 1/3 of all stainless steels produced.

1.4301 is characterised by its good weldability with electrical processes. Even without heat treatment, the steel is corrosion-resistant due to its low carbon content. The carbon content must be below a percentage of 0.08, although in practice values below 0.05% are now possible. It also has very good polishability and can be flexibly shaped. It is approved for temperature stresses up to 600 °C. Especially in the polished state, its high-quality appearance is also protected.

X5CrNi18-10 is a relatively soft, nickel-containing, non-ferromagnetic austenitic steel. To keep the material rust-free and scale-resistant, 1.4301 contains a minimum of 13% chromium.

We use stainless steel 1.4301.

We now use 1.4301 stainless steel for most of our products. Compared to galvanised steel, this has the advantage of increased durability and sustainability. Our demand on a manufactured product is that it lasts a lifetime.

Powder coating is a tried and tested process for finishing our surfaces. In this process, electrostatically charged powder coatings are applied to the respective workpieces with the help of a spray gun. The parts then travel along a conveyor system into the oven for baking. At temperatures of around 180 degrees Celsius, the structures of the powder and the coated surface cross-link with each other. The heating process gives the powder a high-quality, smooth or evenly structured surface. Accordingly, we powder-coat metal parts such as steel, stainless steel, aluminium or other electrically conductive materials.

The advantages of powder coating include high corrosion protection and strong resilience. Coated parts are impact and scratch resistant as well as resistant to chemicals and weathering.

Powder coating is also suitable for use on aluminium and other electrically conductive materials.

Powder coating is a particularly environmentally friendly surface technology, because no solvents or thinners are used in powder coatings. In addition, the powder coating process conserves resources, because the paint that is wasted during application can be recovered.

Material 1.4016 is part of the stainless steel group and is also known as AISI 430 or X6Cr17.

This is called ferritic steel and has a maximum chromium content of 18% (minimum 16%). Ferritic Steel is strongly magnetic, in contrast to austenitic steel. The special property of stainless, ferritic chromium steel lies in its ferritic microstructure. This means that 1.4016 is resistant to stress corrosion, which is usually the neuralgic point in austenitic stainless steels. The shortcoming is the poor weldability of the material.

The material is characterised by its good bending, deep-drawing and polishing properties. The insensitivity to stress corrosion cracking and the basic resistance to alkaline solutions, moisture or diluted organic acids, for example, should also be emphasised. Corrosion resistance in saltwater environments is not given.

We now use stainless steel 1.4016 for most of our powder coated products, which do not require welding. Compared to galvanised steel, this has the advantage of increased durability and sustainability. Our demand on a manufactured product is that it lasts a lifetime.

We use both terms equivalent, therefore the grinding pattern of our products always corresponds to 240 grit. This number stands for the roughness of the abrasive. The surface is matt.

General information

At Briefkasten Manufaktur, only high-quality materials are selected and processed, which guarantee durability and timeless elegance. Please bear in mind, however, that noble materials in particular need to be cared for. Even normal environmental influences can cause soiling and even surface changes. Particularly in industrial conurbations or at sea, deposits in the form of flash rust can occur and the material can be attacked. Here, systems should be cleaned and maintained more frequently.

Stainless steel

One of the materials we use for our products is stainless steel. This steel is characterised by its resistance to water, water vapour, humidity, food acids and weak organic and inorganic acids when used and maintained as intended. After the letterbox has been installed, it should be cleaned for the first time to remove any dirt caused by storage, transport or construction or installation work. Protective layers of paper, foil or adhesive residues must be completely removed after assembly, as they can lead to corrosion. The letterbox should then be maintained approx. every 3 - 4 weeks. We recommend our stainless steel maintenance spray. Please note: The cleaners must not contain any hydrochloric acid, chlorides or hydrocarbons. Under no circumstances should steel wool, steel brushes or similar be used for cleaning stainless steel, as such aids damage the protective surface and enable the formation of extraneous rust through abrasion. Corrosion caused by flash rust is excluded from the warranty. Stainless steel surfaces must always be cleaned in the direction of the rust.

Aluminium

Oxydising or mechanically acting cleaning agents must not be used as they attack the anodised layer. Caution! Protect aluminium parts from cement, lime, plaster, etc.

Glass/Plexiglass

Acrylic glass (Plexiglas) must not come into contact with organic solvents such as thinners, alcohols, fuels, etc. Glass cleaners also usually contain alcohols. Glass cleaners also usually contain alcohols. For cleaning, use only clear water with a few drops of washing-up liquid and a soft sponge. Dust must never be wiped away dry.

Powder coatings

Water and small amounts of a mild cleaner can be used to clean the surface of the powder coating. If absolutely necessary, a small amount of turpentine substitute can also be used. Then rinse with water and a mild cleaner!

Painted surfaces

We recommend weekly cleaning and sealing with car wax at least four times a year for painted surfaces! For cleaning, use only clear water with a few drops of washing-up liquid and a soft sponge. Painted surfaces must also be dried and sealed with car polish. Caution: Do not use cleaning agents containing vinegar.

Lock and hinges

Please only maintain the cylinder lock with a special lock care spray. This way you can enjoy a functioning letterbox lock for a long time. It is best to clean and maintain letterbox hinges twice a year

You can find care and cleaning products in our care guide.

Please note: The cleaners must not contain salts, chlorides or hydrocarbons. Under no circumstances should steel wool, steel brushes or similar be used for cleaning stainless steel, as such aids damage the protective surface and enable the formation of extraneous rust through abrasion. Corrosion caused by rust film is excluded from the warranty.

Templates for our name badges in PDF format. You can label them digitally, print them out yourself and use them directly. We recommend printing on thicker paper or transparent film.

Spare parts for each product can be found directly on the product pages below the product description.

In the spare parts shop for Briefkasten Manufaktur Lippe letterbox systems and letterboxes you will find important spare parts from nameplates to letterbox locks.

The manufactory

We already offer 3D configurators for our series products so that they can be individually designed by the customer and manufactured by us. In addition, further customisations are possible in cooperation with our product development department. Please note that, depending on the workload of the manufactory, we unfortunately also have to refuse requests.

Owing to our product development, we are very flexible and can respond to many details in large-scale or very high-quality projects. Our designers regularly develop new products based on customer data. The product developments then often find their way into series production, so that they also remain monetarily interesting.

The term "Manufaktur" comes from Latin and means manual work in the broadest sense. The modern manufactory is a business that stands between the traditional craft and the modern factory. Unlike in the factory, our employees still produce a lot by hand. Each employee is responsible for many different work steps and manufactures the product to its full extent. There is very little division of labour, as is common in the modern factory. This enables us to manufacture our series products individually according to customer requirements.

Custom-made products are also possible, depending on the workload of the factory.